KOSTENLOSE LIEFERUNG FÜR ALLE PRODUKTE* IN GANZ EUROPA AUCH IN CH/UK/NO (*ausgenommen Messestände)

Product information

Technical specification

Questions and Answers

Main product features

Tool-free assembly

Modular

Silicon Egde System (SEG)

Customizable

Edge lighting

Double-sided print

Application

Booth element

Participation in conferences

Promotional events

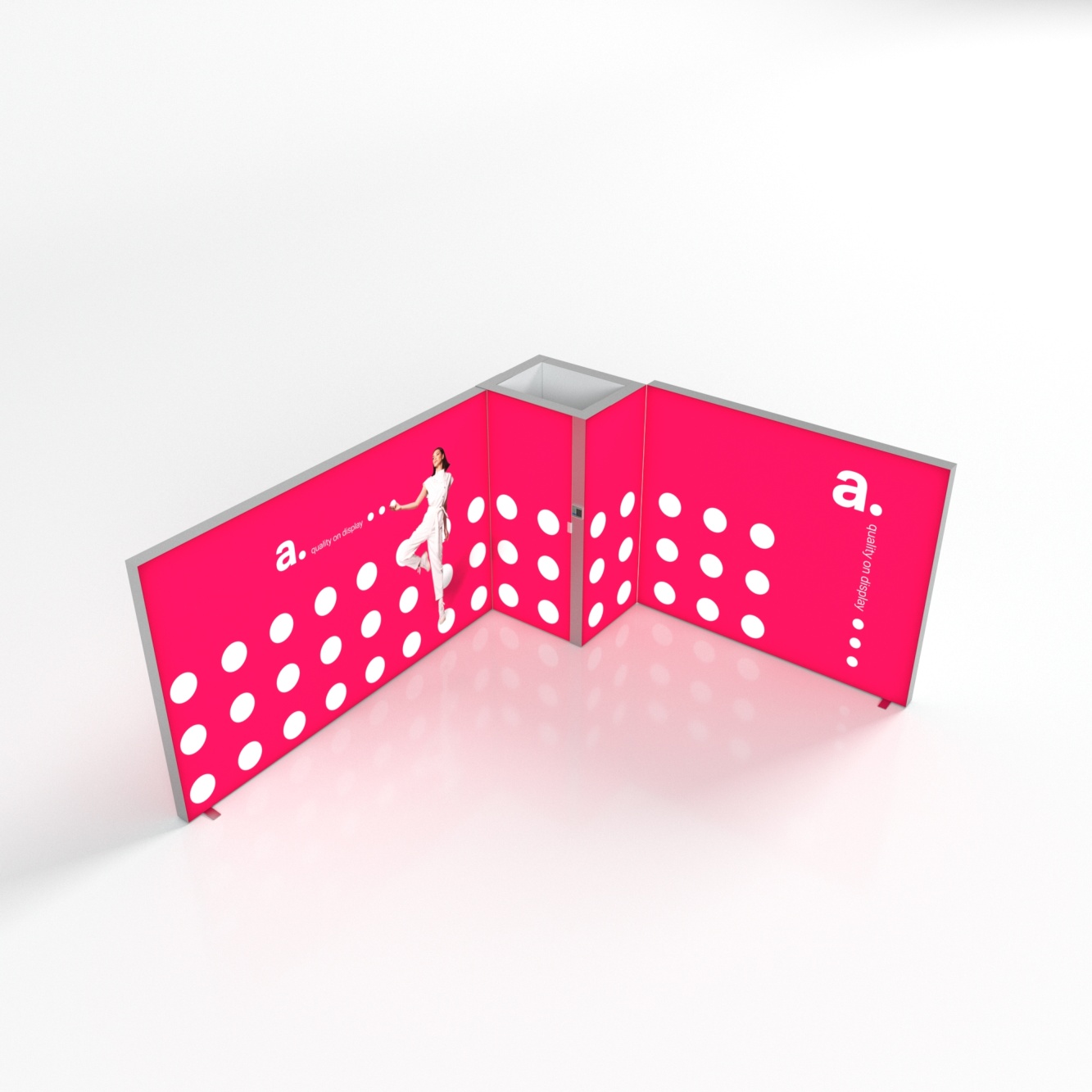

Der LMD Messestand ist ein beleuchtetes, zweiseitiges Ausstellungssystem, das Ihre Marke hervorheben und einen beeindruckenden Präsentationsplatz schaffen wird. Dieser Typ von Messestand besteht aus maßgeschneiderten Leuchtkästen. In ihrem Inneren sind LED-Dioden installiert, die textile Drucke mit Ihren personalisierten Grafiken gleichmäßig beleuchten. Der Aufbau des Messestands erfolgt mit Inbusschlüsseln.

Advantages

Advertising message highlighted by lighting

The construction of the profiles we use to make our LMD exhibition booths is designed to ensure even illumination of graphics from both sides of the display. This is thanks to the wide profile, measuring 14 cm in width, and the placement of LED strips. As a result, LMD trade show displays are precisely illuminated, and the graphics look particularly impressive.

High-quality prints

By opting for an LMD system trade show booth, you will also gain high-quality prints, on which your personalized graphics will be placed. To create them, we use the sublimation printing method. This modern technique is not only ecological but also allows us to achieve vivid graphics and deep, saturated colors. Thus, your trade show construction will not only fit well into the graphic identification of your brand but will also become an impressive business card. The material we use for printing is a type of backlit fabric. Thanks to its properties, light is excellently diffused, which translates into an even better visual effect. Additionally, after dismantling the system, the prints take up little space and do not crease.

Personalization of the booth

Thanks to the advanced technological processes we use in our production line, we can prepare professional LMD system trade show booths according to your needs. Although the standard wall height is 250 cm, we can also prepare other dimensions. As a result, you will gain tailor-made exhibition stands for your business.

Possibility of arranging a backstage area

As you can see, in selected configurations of the LMD booth setups available here, there is an option for a small office area. Such a backstage area greatly facilitates work at trade shows, as personal items or additional promotional materials can be stored inside. Additionally, shelves can also be added to the set. Therefore, if you attend trade shows with a booth setup prepared based on the LMD system, you will gain not only an effective advertising medium but also a comfortable workspace.

Assembly of the exhibition booth

The procedure for assembling the system is not complicated and requires basic manual skills. To erect the entire structure, individual elements must be connected and tightened using an Allen key.

See other products in this category

adFloorModular floor adFloor

5 949,00 zł

LMD Ready-made kits

Product code:

adFrame LMD 3x2 U stand

Dimensions

3x2

3x3

4x3

5x4

Booth Type

Row

Corner

Semi-island

Configuration

With printing

No printing

Only printing

Printout

One side

Double side

Fastest order fulfillment time

Convenient payments for verified Partners

Dedicated Customer Care Service

Order fulfillment time:

13.855,00 PLN

Net

17.041,65 PLN Gross

Price components

17.041,65 PLN Gross

Add to cart

Available quantity: 1